Automated logistics Details >>

[Zhongshan Chen Xiang automated logistics transportation system]

To provide you with a full range of automated logistics solutions, to improve production efficiency and minimize non-value added work processes and bottlenecks, the solution reduces the total for each product waste and energy consumption, thereby reducing manual operations on the environment and dependence. Enables the production cycle time in half.

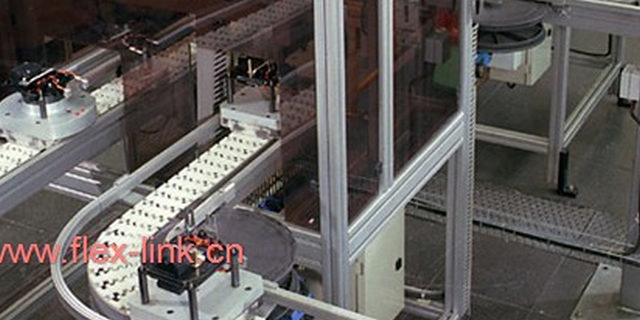

The logistics system can easily achieve product confluence, diversion, 180 degree rotation, vertical or inclined improved caching, aerial transport, the minimum turning radius R160mm, the product can be easily transported needs and maximize space-saving transport.

The logistics system in Sweden has thirty years of history, mainly used to transport SKF bearings, due to its highly efficient and flexible features, soon to be food, beverages, pharmaceuticals, cosmetics, tobacco, electronics and other industries widely used in recent years, China´s factories are outside the purpose of introducing a large number of the system, the current Chinese domestic large scale introduction of this system has Unilever, Procter & Gamble, Flextronics, Avon, United States, Amway, perfect, Colgate Blue Moon, Nestle, Watson, Baxter medical, pharmaceutical and other thirty-nine, become a tool to cut costs.

Increase the profitability of a manufacturing unit there are three main ways:

Improve production efficiency increased shipments

Reduce operating costs

Reduce working capital

Chen Xiang, automated production process solution, all these problems can be improved.

Shipments increased efficiency,

By balancing the production processes, reduce bottlenecks

Reduce waiting time

Decrease over time, increase the flexibility of the line, to maximize production capacity

Perfect quality assurance and increase productivity - reducing nonconforming

Reduce operating costs

Minimize non-value added work

Reduce the power consumption per unit of production

Reduce labor management

Space-efficient solution, that the ability of plants per square meter

In sales and service, and lower total cost of ownership (TCO)

Reduce capital employed

Reduce finished goods inventory

Reduce work-in-progress (WIP)

Better use of the factory floor